Biomass Co-firing

#GS-03 Environment

For Prelims:

About Biomass Co-Firing:

- Biomass co-firing is the practice of substituting a part of the fuel with biomass at coal thermal plants.

About Biomass:

- Biomass is plant or animal material used as fuel to produce electricity or heat. Examples include wood, energy crops and waste from forests, yards, or farms.

- Approximately 32% of the total primary energy use in the country is still derived from biomass and more than 70% of the country’s population depends upon it for its energy needs.

- However this number is slightly misleading as most of this represent inefficient and pollution causing fuels such as fire wood or cow dung.

For Mains

How does Biomass co-firing work?

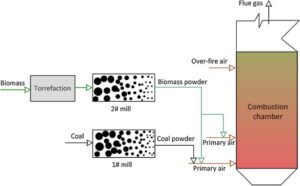

- Biomass co-firing stands for adding biomass as a partial substitute fuel in high efficiency coal boilers.

- This process is done in the following steps:

- Coal and biomass are burned together in boilers that have been designed to burn coal.

- The existing coal power plant needs to be partly reconstructed and retrofitted in order to suit this function.

Advantages of Biomass co-firing:

- Co-firing is an option to convert biomass to electricity, in an efficient and clean way, and to reduce GHG (Greenhouse Gases) emissions of the power plant.

- Biomass co-firing is a globally accepted cost-effective method for decarbonising a coal fleet.

- Biomass co-firing can help to find a profitable solution to the problem of stubble which is causing massive air pollution in the NCR region.

- According to experts Biomass can replace between 20% and 50% of the coal used in thermal power generation.

- However currently India is aiming to replace 5-7 per cent of coal with biomass which can save 38 million tonnes of carbon dioxide emissions as well as millions in foreign exchange.

Challenges in meeting the target:

- According to the ‘National Mission on use of biomass for coal thermal power plants’ set up by the Union Ministry of Power around 95,000-96,000 tonnes of biomass pellets are required per day for co-firing.

- But India’s pellet manufacturing capacity is 7,000 tonnes per day at present even though a surplus 228 million tonnes of agricultural residue is available in the country.